Paper comes in different types, with different sizes, weights, thickness and finishes. Getting the right types of paper for your office printing needs may be a little complicated. However, grasping the basics of paper types will help you make the right choices while stocking up on your office supplies. Office documents serve different purposes and as such, there are different types of paper suitable for each need. Read on to find out the common types of paper and a brief description of each. Many catalogues and brochures are made from paper.

Bond Paper

This paper is more durable and is commonly used in electronic printing. The basic size is 17 inches by 22 inches and weight range is between 16 and 36 pounds. The size may also vary slightly. It is commonly used to make letterheads, envelops, invoices or most documents printed using laser and inkjet printers.

Bristol Paper

Also known as Bristol board, this paper is a heavyweight, thick and uncoated paper. The basic size is 22.5 inches by 28.5 inches with a 0.006 inch thickness. Its strength makes it perfect for use in making book covers, tickets, brochures, file folders, among others.

Recycled Paper

If you are looking to reduce your environmental impact, then using recycled paper may be one step in fulfilling this goal. It is important to note that recycled paper may be slightly expensive than the standard “virgin paper.” This is because it is generally produced in low quantities and hence, per unit production cost may be high. That said, the paper can be used for printing most office documents such as memos and reports.

Index Card

Index card comes in three sizes, 3 inches by 5 inches, 4 inches by 6 inches and 5 inches by 8 inches; and three weights: 90, 110, and 140 pounds. The paper is usually thin and stiff, and is perfect for making magazine inserts, postcards, and index cards. It is budget-friendly and holds ink well, making it ideal for most print projects that require durable paper.

Tag Paper

This type of paper is tough and durable, making it ideal for frequent handling. It is commonly used in making print hand-tags that can be found on consumer goods.

Text Paper

These are uncoated and can be used to satisfy a variety of office requirements such as printing office stationery, letterheads or envelops. They are economical, and with their multiple uses in the office, they make a good choice for normal office use.

These are uncoated and can be used to satisfy a variety of office requirements such as printing office stationery, letterheads or envelops. They are economical, and with their multiple uses in the office, they make a good choice for normal office use.

Coated Paper

These types of paper usually come with a clay coating to create a gloss on the paper surface. The coating gives a shining effect and is better in holding ink as compare to uncoated paper. There are two major types of coated papers: gloss coated paper and matt-coated paper. Gloss coated paper is more shiny and hence, can be used in making brochures and flyers. On the other hand, matt-coated paper is not shiny as it is coated with matt instead of gloss. This eliminates the glare that comes from shiny paper, making it ideal for making reports or leaflets. In between gloss and matt, there is silk coated paper with a silky and smooth coating. It has multiple uses, including making magazines and books.

Today, wood is purposely harvested for half of the material for use in paper today and the rest of the material comes from recycled cloth, recycled newspapers and vegetable matter. Paper experts create fine-grade paper for money and security certificates, which are made from cotton and linen, which are cleaned, cut and boiled before they are used. There are four steps to the paper manufacturing process: Pulping, beating, making the paper and beating.

Today, wood is purposely harvested for half of the material for use in paper today and the rest of the material comes from recycled cloth, recycled newspapers and vegetable matter. Paper experts create fine-grade paper for money and security certificates, which are made from cotton and linen, which are cleaned, cut and boiled before they are used. There are four steps to the paper manufacturing process: Pulping, beating, making the paper and beating.

Paper is taken to a recycling center where other recyclable material is sifted from the paper the paper is then sorted into different grades, such as mixed paper, newspaper, pup substitutes and deinked paper that is of high grade. The paper is then stored in bales after sorting and is then transferred to a mill for processing once the mill needs it. The mill shreds the paper and the heats it and is then pressed to remove any adhesives. After pressing, it is spun to clean it and to remove ink and then it is sent to heated rollers that dry the paper and the paper is then put onto paper rolls to be reused.

Paper is taken to a recycling center where other recyclable material is sifted from the paper the paper is then sorted into different grades, such as mixed paper, newspaper, pup substitutes and deinked paper that is of high grade. The paper is then stored in bales after sorting and is then transferred to a mill for processing once the mill needs it. The mill shreds the paper and the heats it and is then pressed to remove any adhesives. After pressing, it is spun to clean it and to remove ink and then it is sent to heated rollers that dry the paper and the paper is then put onto paper rolls to be reused.

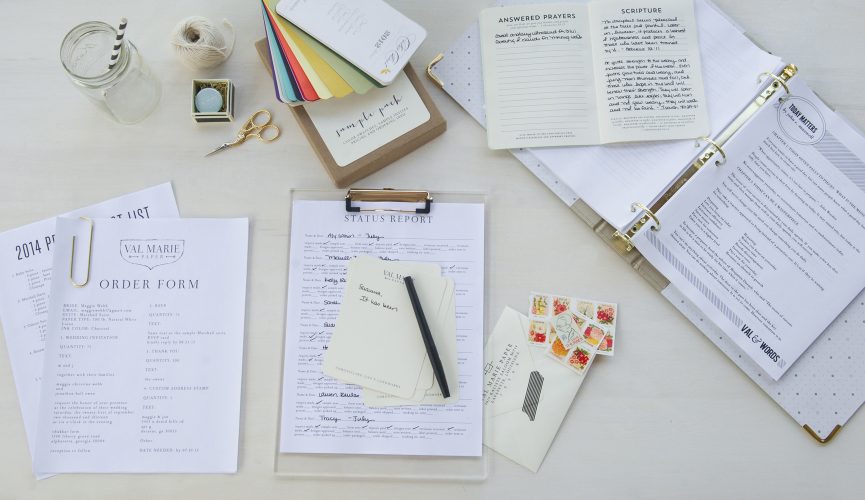

Going green will eliminate manual filing of documents. In place of that, you are spoilt of choice with the different paperless filing systems to help in managing your documents. Different filing systems have different features, benefits, and costs, and your choice will depend on your business needs. Some examples include PDFelement for Business to edit and store your PDF and scanned documents or CrashPlan easily back-up your documents.

Going green will eliminate manual filing of documents. In place of that, you are spoilt of choice with the different paperless filing systems to help in managing your documents. Different filing systems have different features, benefits, and costs, and your choice will depend on your business needs. Some examples include PDFelement for Business to edit and store your PDF and scanned documents or CrashPlan easily back-up your documents.